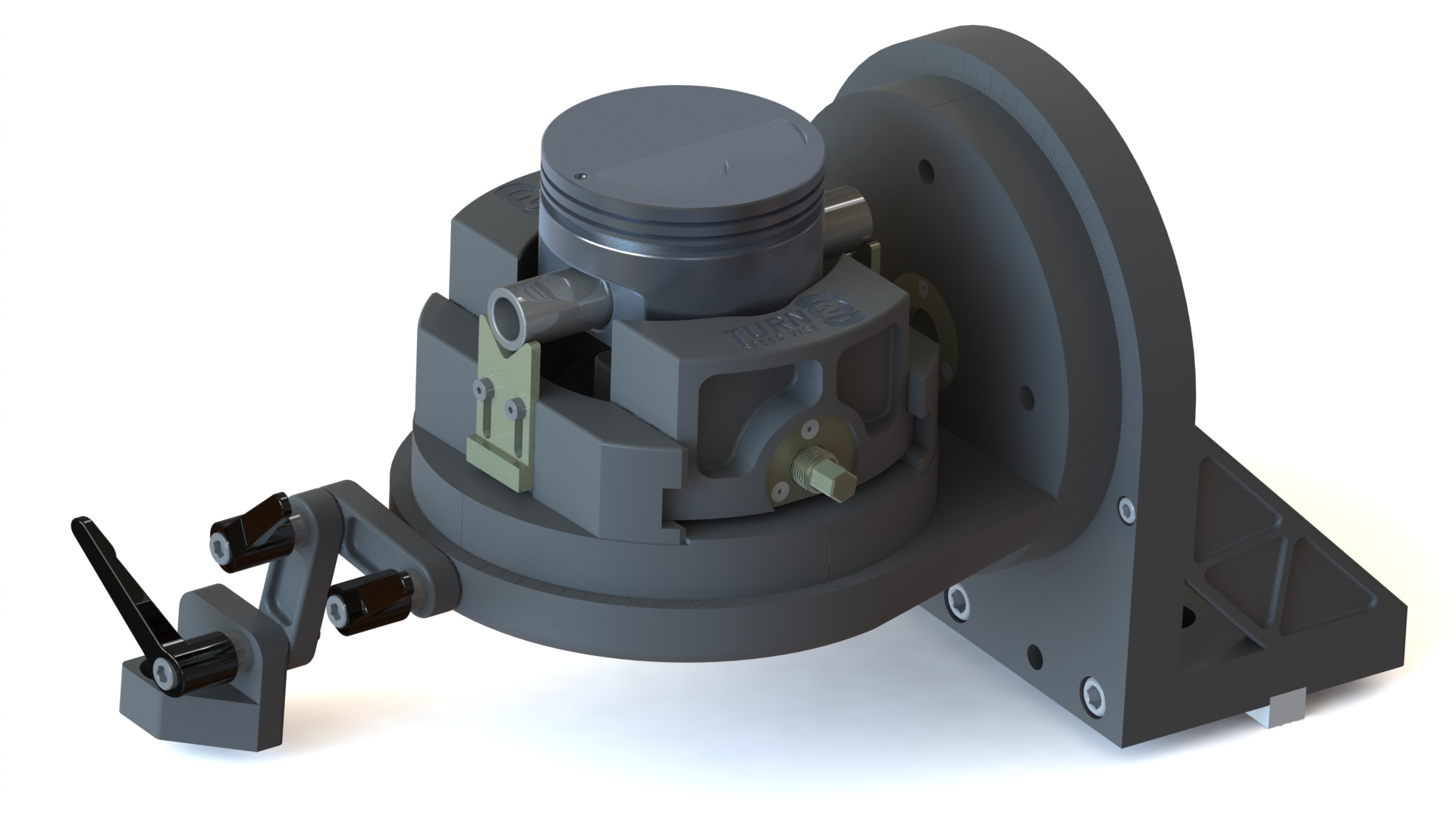

The Turn 2 Speed Vise is, in my opinion, the most rigid and versatile piston vise on the market. It all started from machining some valve pockets and fly-cutting some piston tops for a client using a well established competitors vise. I found that the vise lacked repeatability and rigidity. It was also sort of a pain to set up quickly and accurately.

I thought, “There has to be a better way!” Piston vises have been made the same for decades. I hope you find the Turn 2 Speed Vise refreshing, inspiring and a joy to use. There are probably lots of uses for this system that I haven’t even thought of yet. If you have a project you would like to fixture on it and need some assistance, please feel free to contact me at Davenport Designs LLC. There is a link on the home page.

The main features I was aiming for in the design were:

- Ease of use

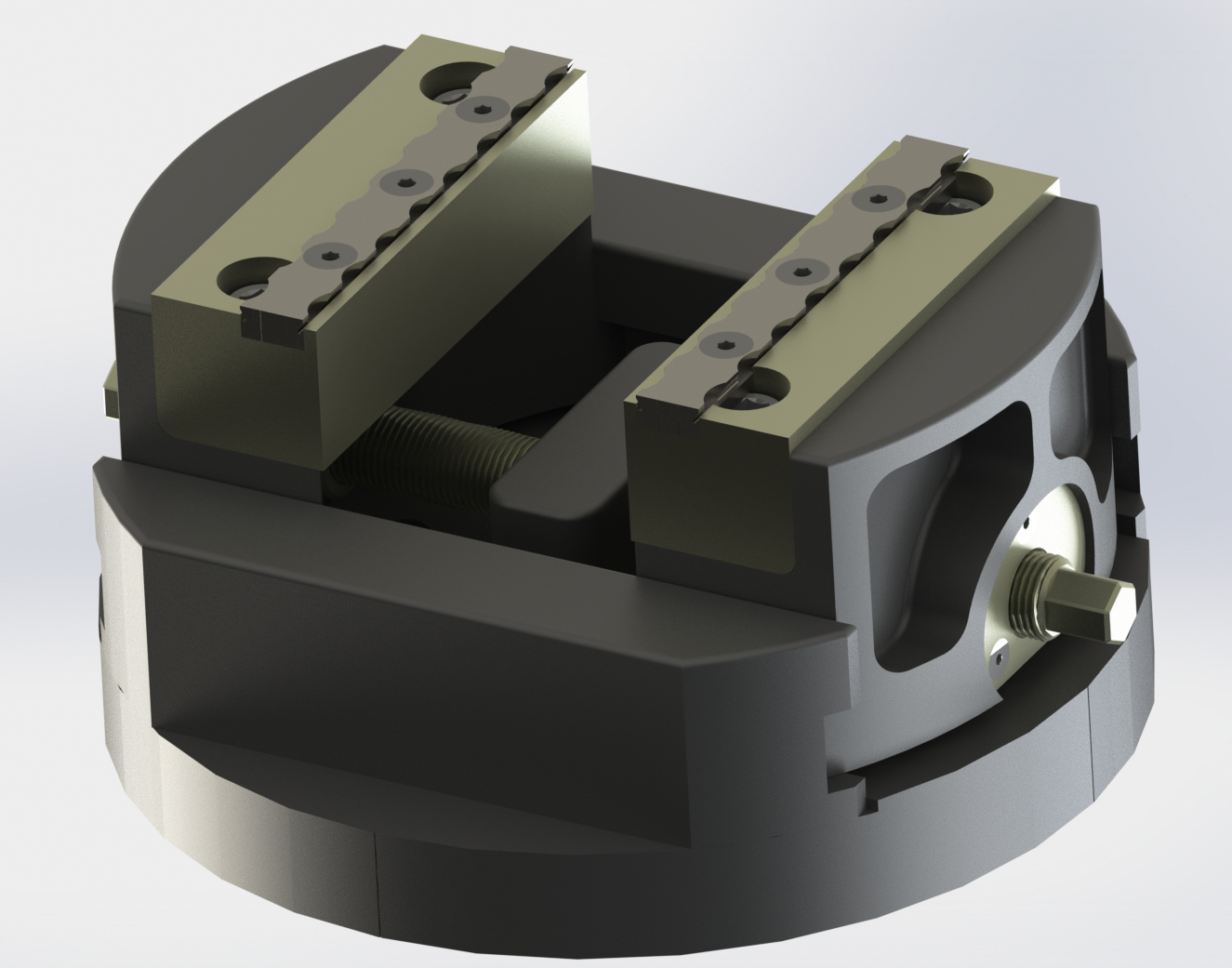

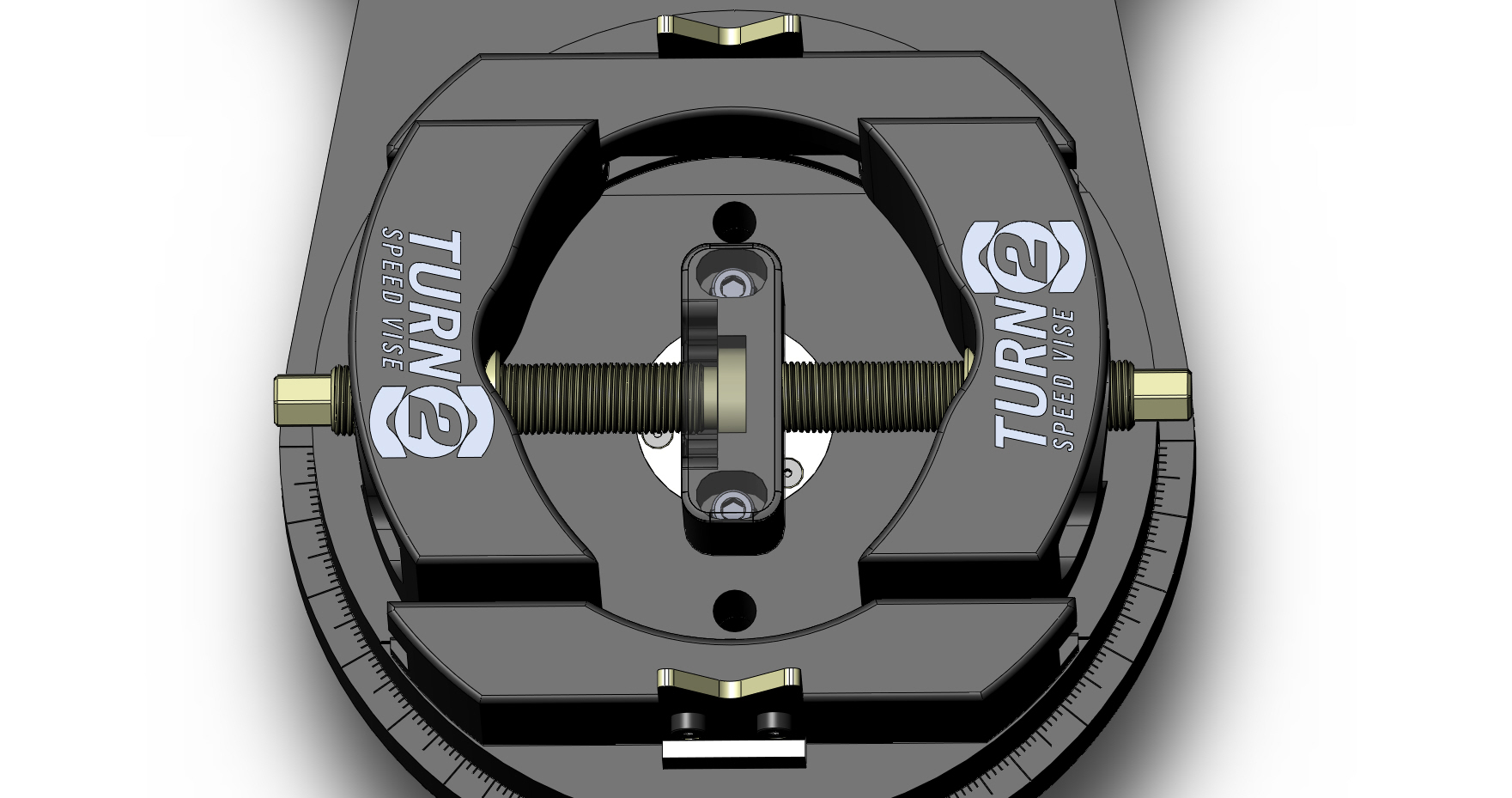

- Ease of use is captured by several features. First is having to use just two lock bolts to locate the piston in any position needed. Most other vises have four to eight bolts. The self-centering vise is very simple and straightforward to use. It does take a simple initial effort to dial in the setup, but once you set it, you can forget it. Dialing in angles is simple due to the degree marks that are engraved on both rotational axis. The fixture base is keyed to allow for quick setups on your worktable.

- Rigidity

- I think the two main issues that made the competitors vise lack rigidity were loose manufacturing tolerances and inferior material choices allowing an adequate design to become flawed. All the components of the Turn 2 Speed vise are made of quality American made materials. They are then machined to exacting tolerances. I put all I can into making these and quality is my main objective. I designed the Turn 2 Speed vise to be as rigid as practically possible. This vise is proudly made in America and not a one time use/ throw away piece. Please see the pics, I hope they speak for themselves. The same goes for when you use it.

- Repeatability

- Extensive testing has found excellent repeatability. The pin V’s accurately and consistently locate and orient the piston using the wrist pins. The two V-jaws of the self centering vise rigidly grip the piston in four spots.

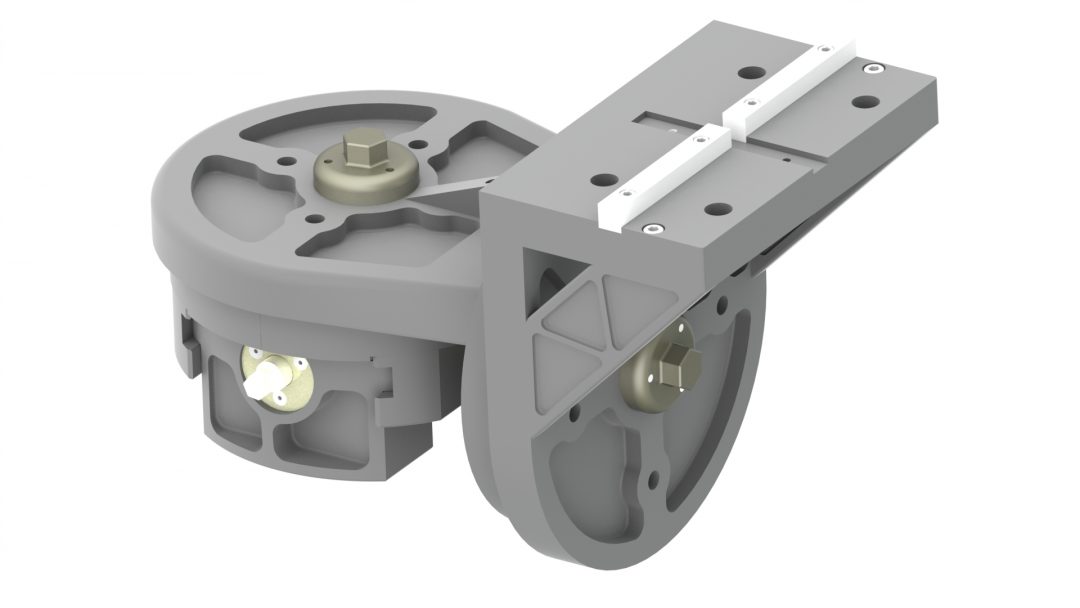

- Versatility

- The versatility is only limited by one’s imagination. It’s main focus was piston work, but as you will see, it can go much farther. There is a lot in the works for fixturing already. The two main ones are for machining/fixturing Holley carburetors and fixturing single cylinder heads for machine work or hand porting. Blank platters are available also if you want to create your own fixture. If you have the ABS piston vise, I will end up offering a platter so you can mount the chuck on this fixture.

Please take a look at more details highlighted below and also feel free to have a look at the shop website. We are open to questions and feedback, if you have any.